Online CNC Machining Services: A Smart Manufacturing Solution

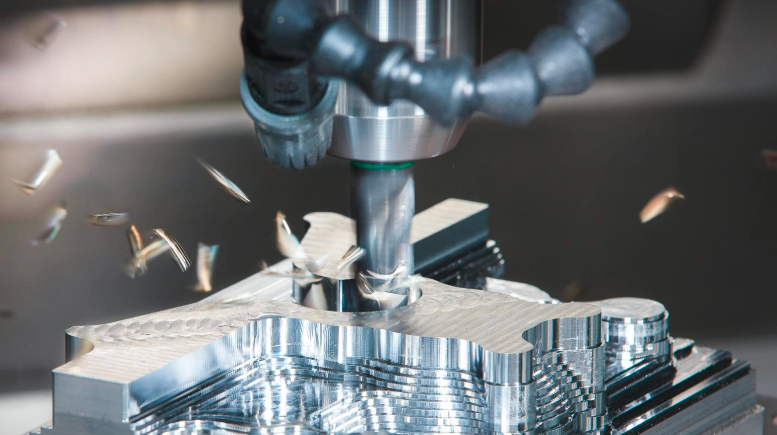

In today’s fast-paced industrial world, manufacturers and businesses are constantly looking for efficient ways to produce high-quality parts with precision and reliability. Online CNC machining services have emerged as a revolutionary approach to manufacturing, offering businesses a convenient and cost-effective way to obtain custom-machined components without traditional barriers.

This article explores online CNC machining services, their advantages, applications, and how they are transforming the manufacturing industry.

What Are Online CNC Machining Services?

Online CNC machining services allow businesses, engineers, and product designers to upload their designs to a digital platform, receive instant quotes, and place orders for custom-machined parts. These services leverage computer numerical control (CNC) technology, which automates machining processes to ensure accuracy and consistency.

Unlike traditional machining, where customers must visit a machine shop, negotiate costs, and wait for manual processing, online CNC machining simplifies the entire process. Orders are processed efficiently using cloud-based platforms, ensuring quick turnaround times and precision machining.

How Online CNC Machining Services Work

Online CNC machining follows a streamlined process that enhances efficiency and reduces lead times:

1. Uploading the Design

Customers upload CAD (Computer-Aided Design) files to the online platform. Supported file formats typically include STEP, IGES, and STL.

2. Instant Quotation

The system analyzes the design, considers material choice, complexity, and machining requirements, then provides an instant price estimate.

3. Material Selection

Users select from a range of materials, including metals (aluminum, stainless steel, titanium) and plastics (ABS, PEEK, nylon, etc.) based on their application needs.

4. Production and Quality Control

Once the order is confirmed, CNC machines begin manufacturing the part with precision. After machining, parts undergo inspection and quality control to ensure they meet the required specifications.

5. Delivery to the Customer

Finished parts are shipped directly to the customer, reducing the need for on-site visits or manual handling.

Benefits of Online CNC Machining Services

online CNC machining servicesoffer numerous advantages that make them a preferred choice for businesses and engineers.

1. Fast and Convenient

With an online platform, users can get instant quotes, place orders, and track production without visiting a physical machine shop. This saves time and accelerates product development.

2. Cost-Effective Manufacturing

Online CNC machining eliminates the need for in-house machining facilities, reducing overhead costs. Customers only pay for what they need, making it a budget-friendly option.

3. Wide Range of Materials and Finishes

Most online CNC machining platforms provide extensive material choices, including metals, plastics, and composites. They also offer post-processing options like anodizing, powder coating, and polishing for a professional finish.

4. High Precision and Quality

CNC machines operate with high accuracy, ensuring tight tolerances and consistency across multiple parts. This is especially important for industries like aerospace, medical, and automotive manufacturing.

5. Scalable Production

Whether you need a single prototype or a large production run, online CNC machining services can accommodate different order sizes efficiently.

6. Global Access to Expertise

By using online CNC machining services, businesses can connect with experienced manufacturers worldwide, accessing high-quality machining capabilities regardless of their location.

Applications of Online CNC Machining Services

1. Prototyping for Product Development

Startups and engineering firms use online CNC machining to quickly produce prototypes for testing and refinement before full-scale production.

2. Aerospace Industry

Aircraft parts require extreme precision and durability. Online CNC machining provides high-quality aluminum, titanium, and stainless steel components for aerospace applications.

3. Medical Device Manufacturing

The medical sector relies on CNC machining for custom implants, surgical instruments, and prosthetics. The accuracy of CNC technology ensures compliance with medical standards.

4. Automotive Components

Car manufacturers use CNC machining for engine parts, transmission components, and structural elements that require high precision.

5. Electronics Industry

From heat sinks to enclosures and connectors, CNC machining is widely used in electronics manufacturing due to its ability to create intricate designs with high accuracy.

6. Custom Tooling and Equipment

Manufacturers use CNC machining to produce custom tools, jigs, and fixtures that enhance production efficiency.

Online CNC Machining vs. Traditional Machining

| Feature | Online CNC Machining | Traditional Machining |

| Accessibility | Available globally, order from anywhere | Requires physical visits to a machine shop |

| Speed | Instant quotes, faster turnaround | Longer processing times |

| Cost | Competitive pricing, no overhead costs | Higher costs due to manual labor |

| Material Choices | Wide selection of metals and plastics | Limited based on shop capabilities |

| Scalability | Suitable for small and large production runs | Less flexible for on-demand production |

| Customization | High customization with post-processing options | Limited customization |

Choosing the Right Online CNC Machining Service

Selecting the right online CNC machining service provider is essential to ensure quality and reliability. Here are key factors to consider:

1. Experience and Reputation

Look for platforms with positive reviews and proven expertise in precision CNC machining.

2. Material and Finishing Options

Ensure the service provider offers the materials and finishes required for your project.

3. Pricing and Lead Times

Compare quotes from multiple providers to find the best balance between cost and delivery speed.

4. Quality Assurance

Check if the provider follows ISO certifications and quality control standards to guarantee precision.

5. Customer Support

Reliable customer support ensures smooth communication and problem resolution during the machining process.

Future of Online CNC Machining Services

The evolution of online CNC machining services is driven by technological advancements and increasing demand for rapid manufacturing solutions. Here are some future trends to watch:

1. AI-Powered Quoting and Optimization

Artificial intelligence is being integrated into CNC platforms to provide more accurate pricing, optimize machining paths, and reduce production costs.

2. Increased Automation and Robotics

The rise of robotic machining and automation will further enhance efficiency and reduce lead times.

3. Sustainable Manufacturing Practices

Companies are adopting eco-friendly materials and energy-efficient CNC machines to reduce environmental impact.

4. Blockchain for Supply Chain Transparency

Blockchain technology may be used to track and verify CNC machining orders, ensuring quality control and secure transactions.

5. Hybrid Manufacturing Integration

Combining CNC machining with 3D printing (additive manufacturing) will create new possibilities for complex designs and faster production cycles.

Conclusion

Online CNC machining services have transformed the way businesses and engineers access precision machining. With fast quoting, high-quality production, and cost-effective solutions, these services make it easier than ever to obtain custom-machined parts.

By leveraging technology, online CNC machining eliminates traditional barriers and provides global access to expert manufacturers. Whether for prototyping, mass production, or custom components, this modern approach to CNC machining ensures efficiency, accuracy, and scalability.

As digital manufacturing continues to evolve, online CNC machining services will play a crucial role in shaping the future of industry, offering smarter and more accessible solutions for a wide range of applications.